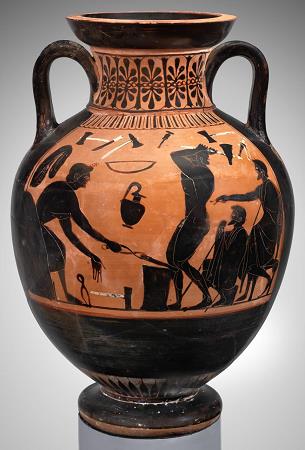

Genre with Blacksmith. A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from other metals, by forging the metal, using tools to hammer, bend, and cut. Blacksmiths produce objects such as gates, grilles, railings, light fixtures, furniture, sculpture, tools, agricultural implements, decorative and religious items, cooking utensils, and weapons. There was an historical distinction between the heavy work of the blacksmith and the more delicate operation of a whitesmith, who usually worked in gold, silver, pewter, or the finishing steps of fine steel. The place where a blacksmith works is called variously a smithy, a forge or a blacksmith's shop. While there are many people who work with metal such as farriers, wheelwrights, and armorers, in former times the blacksmith had a general knowledge of how to make and repair many things, from the most complex of weapons and armor to simple things like nails or lengths of chain. The black in blacksmith refers to the black firescale, a layer of oxides that forms on the surface of the metal during heating. The origin of smith is debated. It may come from the old English word smythe meaning to strike or it may have originated from the Proto-German smithaz meaning skilled worker. Blacksmiths work by heating pieces of wrought iron or steel until the metal becomes soft enough for shaping with hand tools, such as a hammer, an anvil and a chisel. Heating generally takes place in a forge fueled by propane, natural gas, coal, charcoal, coke, or oil. Some modern blacksmiths may also employ an oxyacetylene or similar blowtorch for more localized heating. Induction heating methods are gaining popularity among modern blacksmiths. Color is important for indicating the temperature and workability of the metal. As iron heats to higher temperatures, it first glows red, then orange, yellow, and finally white. The ideal heat for most forging is the bright yellow-orange color that indicates forging heat. Because they must be able to see the glowing color of the metal, some blacksmiths work in dim, low-light conditions, but most work in well-lit conditions. The key is to have consistent lighting, but not too bright. Direct sunlight obscures the colors. The techniques of smithing can be roughly divided into forging, welding, heat-treating, and finishing. Forging, the process smiths use to shape metal by hammering, differs from machining in that forging does not remove material. Instead, the smith hammers the iron into shape. Even punching and cutting operations by smiths usually re-arrange metal around the hole, rather than drilling it out as swarf. Forging uses seven basic operations or techniques: Drawing down. Shrinking. Bending. Upsetting. Swaging. Punching. Forge welding. These operations generally require at least a hammer and anvil, but smiths also use other tools and techniques to accommodate odd-sized or repetitive jobs. Drawing lengthens the metal by reducing one or both of the other two dimensions. As the depth is reduced, or the width narrowed, the piece is lengthened or drawn out. As an example of drawing, a smith making a chisel might flatten a square bar of steel, lengthening the metal, reducing its depth but keeping its width consistent. Drawing does not have to be uniform. A taper can result as in making a wedge or a woodworking chisel blade. If tapered in two dimensions, a point results. Drawing can be accomplished with a variety of tools and methods. Two typical methods using only hammer and anvil would be hammering on the anvil horn, and hammering on the anvil face using the cross peen of a hammer. Another method for drawing is to use a tool called a fuller, or the peen of the hammer, to hasten the drawing out of a thick piece of metal. Fullering consists of hammering a series of indentations with corresponding ridges, perpendicular to the long section of the piece being drawn. The resulting effect looks somewhat like waves along the top of the piece. Then the smith turns the hammer over to use the flat face to hammer the tops of the ridges down level with the bottoms of the indentations. This forces the metal to grow in length much faster than just hammering with the flat face of the hammer. Heating iron to a forging heat allows bending as if it were a soft, ductile metal, like copper or silver. Bending can be done with the hammer over the horn or edge of the anvil or by inserting a bending fork into the hardy hole, placing the work piece between the tines of the fork, and bending the material to the desired angle.

more...