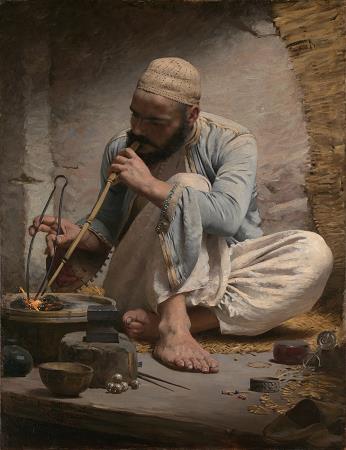

Jeweler. A bench jeweler is an artisan who uses a combination of skills to make and repair jewelry. Some of the more common skills that a bench jeweler might employ include antique restoration, silversmithing, goldsmithing, stonesetting, engraving, fabrication, wax carving, lost-wax casting, electroplating, forging, and polishing. In general, an original design is made and sold using processes such as molding, casting, stamping and similar techniques. The other is original, one of a kind work. The bench jeweler will be a factor in many facets of the process, depending on what is needed and the skills of the worker. When a production piece is contemplated, it may go through a design process that can range from one person with an idea to a full-scale planning stage involving teams of artists and marketing professionals. Eventually, that design will need to be made into a real piece of metal jewelry, which is generally called a model, and the worker who makes it is generally the model maker. This is often considered the highest form of craftsmanship, as the piece must be made true to the design and also to most exacting standards. A good model maker is, along with a fine watchmaker among the most technically skilled workers in any trade. After the model is made and found to be what is desired, it is molded or perhaps entered into a machining process to make copies. Assuming it is molded, multiples of the piece are cast from the mold. See lost-wax casting, which article has a sculptural inclination, though the principles are the same for jewelry casting. The cast pieces will likely need a variety of work done to them, including filing to remove the skin left from casting and prepare for polishing, straightening parts, rounding and sizing rings, and assembling many various parts together using solder. Although the method used is called soldering, it is actually a form of brazing, using solders of the metal being worked, i.e. gold solders for gold pieces, silver solder for silver pieces, etc. All of this is the work of bench jewelers, who at this level are sometimes known as production workers in some arenas. In this context, the bench jeweler is responsible for all of the main work involved in turning a raw casting into a piece of jewelry-filing it, straightening it, assembling parts or adding settings for stones, repairing any problems that might have occurred, and preparing it for stonesetting and polishing. Special-order jewelry is the making of one of a kind items and is not too different from model making. The Main difference between the two is that the special-order piece is made in precious materials, while often a model is not, and the need for exacting precision is nowhere near as high as in model making. Generally the special order jeweler takes a design, either their own or a customer's, and turns it into a piece of finished jewelry from start to finish. This process, like model making, can be fairly simple Wax Carving to be cast into metal, or it can involve very complex fabrication skills building the piece out of the actual metal using a wide variety of skills and tools. Very often both model making and special order involve gemstones, and thus the pieces must be designed and made to properly hold those. It will be obvious that any manufacturer of any product will design a workshop to their own liking and it may defy convention. There are, however, some typical categories that most shops in the jewelry trade will employ. If it is a manufacturing workshop, likely it will begin with the casting room, then to the bench jewelers or goldsmiths, perhaps to the polishing department and maybe to stonesetting. Generally there will be at least one model maker, who may also do special orders, or there may be a dedicated special order department and sometimes even repair, depending on the size of the shop. Usually there is also at least one foreman and also a front office handling management. In addition there might be engravers, enamelists, perhaps a machine shop and others, depending on the product being made. A good shop behaves as a team, with each department doing their part and the work passing back and forth between them as needed. In this situation each worker is a specialist at their job, and though they may have a broader background that becomes useful at times, they generally will not enter into another department's expertise. Each department also recognizes the worker's abilities, so that there may be ten workers called goldsmiths, but one will have simple skills, and another may have greatly higher ability, and so the more or less challenging jobs are assigned accordingly.

more...